Imagine you’re preparing for the biggest event of your life. You’re traveling out of town, and you’ve made specific wardrobe choices to compliment your groundbreaking moment. While packing for your trip, you had to choose between an additional outfit or an extra pair of shoes because your luggage is too small, and you had to decide which outerwear to bring because there wasn’t enough room in your carry-on for more than one jacket. After nearly missing your flight, you land at your destination only to discover the airline has misplaced your luggage. This happens all the time.

Now imagine how convenient it would be if your whole outfit, including your accessories, were instantly emailed to you. Everything you’re wearing, from head to toe, is created digitally, with your designer’s imagination being the only structural limitation. She receives your body measurements through an app and styles your unique, custom-made garments using computer-aided design software without ever meeting you in person. You can save your design, backup your entire wardrobe closet on a hard drive, and print your clothing locally. You can choose which materials to use based on the weather, season, or style preferences, and you can even change colors to suit a special occasion the next time you print. The materials you’re wearing are completely re-usable, so you’re making environmental sustainability a fashion statement. This may sound futuristic because only 1% of the market’s textiles are being recycled, yet forward-thinking fashion designers like Danit Peleg are hard at work; innovating the wearable future of fashion, today.

Peleg has always been curious about the relationship between fashion and technology. Before her studies at Shenkar College of Engineering and Design, Peleg was experimenting with knitting machines, laser cutting, and digital printing. The focus of her studies landed her a prestigious internship at an Avante Garde fashion house in New York, where Peleg had a firsthand look at 3D wearable objects for the first time. Although the materials she worked with were stiff and breakable, Peleg was inspired by the waste-free simulation process and began to explore the design potential for eco-friendly wearables of her own making.

“When I started to learn about the current situation with the global fashion industry and production, I was really, really depressed,” Peleg recalls. “I started to research and learn how fashion design became the second most polluting industry. Being a participating member, I didn’t want to be part of it. We’re using the same technology we used 100 years ago. But now you don’t have to go through tons of inventory and you can see the digital design and even try on the garment with augmented reality.”

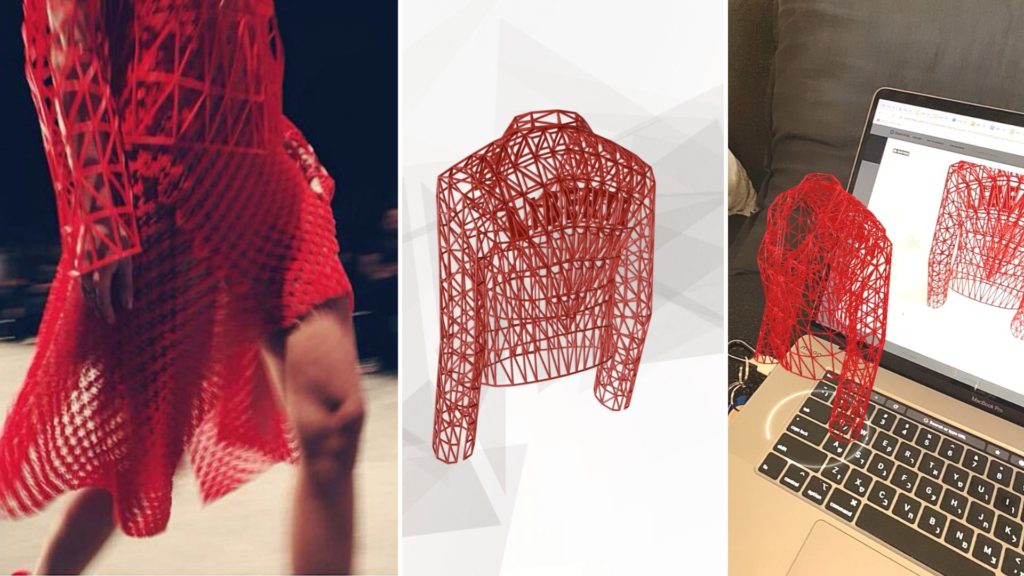

With the opportunity to learn an industrial process that rendered 3D printed wearables unaffordable for the everyday consumer, Peleg was determined to find a cost-effective solution to achieve her brand ambitions. The printers being used were massive, so she needed to scale her process to smaller machines in order to work alone or with a core collaborative team. A chance encounter at Burning Man became the galvanizing gift; a 3D-printed necklace that had been created using a commercially available desktop 3D printer. With her design modeling experience and several 3D printers within arm’s reach, Peleg designed her first 3D-printed wearable fashion collection called Liberty Leading the People, which she launched from home while in her graduating year at Shenker. Her collection of five outfits were made entirely of 3D printed materials—including shoes and accessories. Peleg produced her collection on six 3D printers running 24 hours a day; waking up in the middle of the night to change the ink colors, assemble garments, and try them on her models. Peleg’s innovative spirit drove the success of her collection and propelled her career to the forefront of technological research and development in the fashion industry.

With sophisticated printers now at her disposal, Peleg is dedicated to improving upon 3D print materials that are currently available to the public. The focus of her research involves the combination of flexible structures with flexible materials to create softer fabrics. Most of the materials she’s currently using look and behave like rubber; they’re soft, yet nothing like cotton, silk, or leather. Her collaboration with Moon Creative Lab develops sustainable materials for 3D printers that behave like fabrics and are still 100% reusable and recyclable. The traditional process to create a fashion collection results in tremendous waste, leftover fabric, and raw materials that are either buried or burned.

“I imagine all of our clothes can be recycled,” Peleg muses. “You just go to the store, give back your old t-shirt, and get a refund or credit for your next purchase based on the weight—or you can simply reuse your own material,” she emphasized. “You can do something else with it. You’ll have a spool of similar material to wool or cotton or silk, and you’ll be able to choose and reuse your materials over and over.”

Design manufacturing is now so fast that the latest trends can be released every day, which isn’t entirely unlike NFTs on the blockchain. When combined, you can produce an NFT garment with zero inventory, and sell as many pieces as you want. Peleg’s NFTs come with an unlockable folder containing the 3D printable files and a document explaining how to print and assemble your clothing. A virtual file is also included for your avatar to wear the very same garment in the metaverse. An augmented reality filter on Peleg’s Instagram offers the convenience of viewing her clothing in your own home, and if you don’t have access to a 3D printer, Peleg will print your garment in pieces and ship them to you. You also have the option to order the entire garment printed in her studio.

“I believe the proof of provenance and ownership that NFTs offer will help revolutionize fashion, specifically digital and 3D-printable fashion,” Peleg says. “This will enable designers to sell their work directly to customers who will not only want to wear and promote their fashion in the metaverse, but will also print and wear them in the physical world. If you want to prove you own the Gucci bag with its NFT twin, you need to own both the digital and physical piece.”